Bearing technology takes new steps in industrial applications

Recently, bearing technology has taken new steps in industrial applications, bringing rich innovative solutions to various industries. As a key mechanical component, bearings are widely used in fields such as automobiles, aerospace, mechanical manufacturing, and energy, and their importance is self-evident. The emergence of new bearing application technologies will bring more efficient and reliable solutions to these industries.

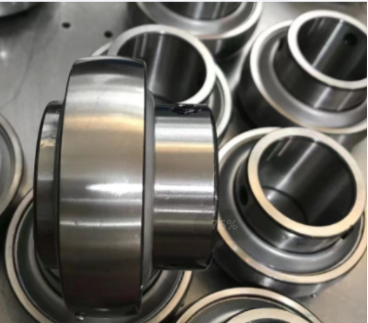

In the automotive manufacturing industry, significant breakthroughs have been made in the application of bearing technology. Traditional rolling bearings are prone to damage and failure in high-speed and high-temperature environments, which limits the performance and durability of automobiles. However, due to the introduction of new materials and processes, jet vortex bearings have become a new favorite in the automotive industry. Jet vortex bearings adopt the principle of aerodynamics. When the vehicle is running at high speed, the weight of the vehicle is supported and suspended by the high-speed rotating airflow, thereby reducing wear and friction, and improving the performance and lifespan of the vehicle.

In the aerospace field, the advancement of bearing technology has significantly improved the performance of aircraft. Traditional metal bearings are prone to failure in the high temperature and high pressure environment of aircraft, leading to an increased risk of aircraft accidents. The emergence of high heat-resistant ceramic ball bearings has solved this problem. High heat resistant ceramic ball bearings are made of ceramic materials, which can maintain stable performance in high-temperature environments. At the same time, due to the lightweight characteristics of ceramics, the weight of the aircraft is reduced, and the fuel efficiency of the aircraft is improved.

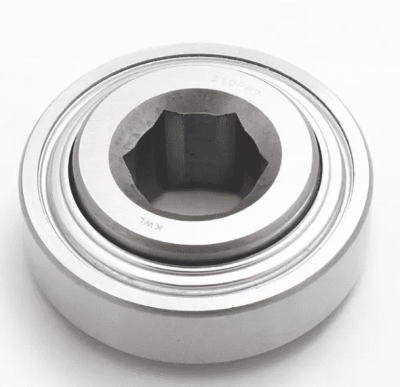

In the field of mechanical manufacturing, bearing technology plays an important role in high-precision machining. Traditional rolling bearings are prone to vibration and instability during high-speed rotation, which limits the accuracy and efficiency of mechanical processing. However, with the emergence of new magnetic levitation bearing technology, this problem has been effectively solved. Magnetic levitation bearings suspend and support mechanical rotating bodies through electromagnetic force, without contacting solid bearings, enabling higher precision and faster precision machining.

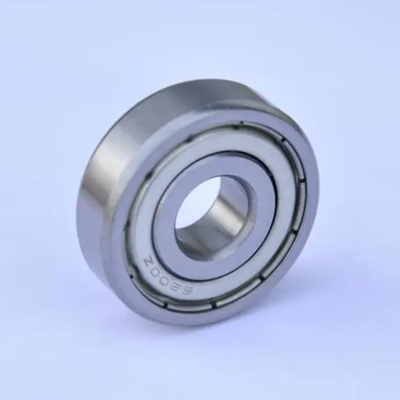

In addition to the above-mentioned application areas, bearing technology also plays an important role in the energy industry and other fields. For example, in wind power generation equipment, the use of low friction rolling bearings can effectively reduce energy loss and improve power generation efficiency.

It can be foreseen that with the continuous innovation and progress of bearing technology, its role in industrial applications will become increasingly important. Whether in industries such as automobiles, aerospace, mechanical manufacturing, or energy, the new application of bearing technology will bring more efficient and reliable solutions to related industries, promoting the development and progress of the industry.