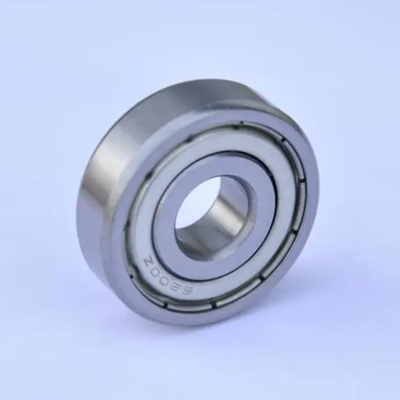

roller bearings

Bearing types:

1 row: NU, NJ, NUP, N, NF, NH, NJV, NFV

2 rows: NNU, NN, SL

4 rows: 4R

In many industrial applications, cylindrical roll bearings (CRB) play an indispensable role. From precision gears for robots and railway machinery, to geared motors for stationary machinery, to gearboxes for mobile devices and speed multipliers for wind turbines, CRBS support a wide range of loads with their superior performance.

The main feature of CRBS is their ability to withstand high radial loads. With careful design, the shoulders of the inner and outer rings can be evenly distributed and thus able to withstand axial loads. When choosing the right bearing type, we also need to consider whether we need to use cage-free or cage-class CRBS.

The cage-free category of bearings is characterized by the use of larger rolls, able to withstand higher loads, but the rotation speed is relatively slow. The cage type bearings have the characteristics of high acceleration, high rotation speed and high radial load, which is suitable for application scenarios requiring high speed and high load.

Let's take a look at the specific types and sizes of cylindrical roller bearings: from the standard range of hole diameters from 20mm to 1250 mm, we have a range to choose from. In addition, there are different titles such as 4R, NU, NJ, NUP, N, NF, NH, NJV, NFV and SL: Cylindrical roller bearings: an important role in industrial applications

I. Introduction

Cylindrical roll bearings (CRBS) play a key role in numerous industrial applications, including robotics, railway machinery, gear motors, transmission boxes for mobile devices, and speed control for wind turbines. Type to choose from.

However, choosing the right bearing type and size is only the first step. In order to ensure the best performance of bearings in industrial applications, we also need to consider other factors such as lubrication, sealing, temperature and vibration. They are designed to withstand high radial loads and, as long as the inner and outer ring shoulders are evenly distributed, can also withstand axial loads. Therefore, when selecting cylindrical roller bearings, we need to consider various factors comprehensively to ensure that our equipment can operate stably and efficiently.

In general, cylindrical roller bearings are strong partners in industrial applications, they can withstand various loads and adapt to different working environments. Through rational selection and use, we are able to maximize their performance and improve the efficiency and reliability of the equipment.

Second, bearing classification

Bearing types are diverse, including 1 row (4R), 2 rows (NU, NJ, NUP, etc.), 3 rows (NNU, NN, SL), etc., and a wide range of sizes, from 20mm to 1250mm of standard bore. These bearings can meet the needs of different applications.

Third, bearing performance

1. No cage category: This type of bearing uses the maximum roller capacity and can withstand higher loads, but the rotation speed is moderate.

2. Cage category: This type of bearing has the performance of high acceleration, high rotation speed and high radial load.

4. Application field

Cylindrical roller bearings are widely used in robotics, railway equipment, mechanical equipment, mobile equipment transmission and wind turbines.

V. Conclusion

Cylindrical roller bearings play an indispensable role in the industrial field with their excellent performance and wide application fields. Its diverse range of types and sizes can meet a variety of different needs, providing a strong support for industrial progress.